A diversity of wire coiling techniques that gives rise to highly sophisticated filaments.

Mitsuwa's wire coiling technology responds to a wide variety of configurations, including continuous coiling, variable pitch coiling, and double coiling, etc. It can coil an ultra-fine wire to high precision and support characteristics problems including selection of properties, shape, and material of the filament.

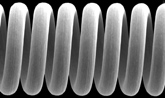

Continuous coiling using core wire

Coiling configurations

Continuous coiling |

Double coiling |

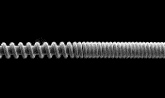

Variable pitch coiling |

| Configuration | Continuous coiling | Double coiling | Variable pitch coiling |

|---|---|---|---|

| Wire diameter | 5μ - | 5μ - | 15μ - |

| Coil outside diameter | 36μ - | 135μ - | 75μ - |

| Coil length | 0.4mm - | 3.5mm - | 3.5mm - |

| Coil pitch *1 | 150% | 1st 200% 2nd 180% |

100% -240% |

| MD/WD ratio | 170% *2 | 140% *3 | 270% *2 |

* Send separate inquiries about dimensions.

*1 Coil pitch: Ratio of distance between wire diameters to wire diameter; values in the table are recommendations.

*2 MD/WD ratio: Ratio of core wire diameter to wire diameter; that for double coiling is the value for the primary coiling.

Coiling machine

|

Core wire removed during coiling

Coil with legs |

Electrode |

Coiling |

| Configuration | Continuous coiling | Electrode |

|---|---|---|

| Wire diameter | 40μ - | 150μ - |

| Coil outside diameter | 75μ - | - |

| Coil length | -100turn | 0.25mm - |

| Coil pitch *1 | 150% | - |

| MD/WD ratio | 500% *2 | - |

* Send separate inquiries about dimensions.

*1 Coil pitch: Ratio of distance between wire diameters to wire diameter; values in the table are recommendations.

*2 MD/WD ratio: Ratio of core wire diameter to wire diameter

|

[Head Office / Main Plant] |