Mitsuwa's microfabrication technologies meet widely ranging needs.

Mitsuwa Electric's outstanding processing technologies are used in making various types of products, such as electrodes and filaments. Review our microfabrication technologies, including wire coiling, heat treatment, and joining technologies.

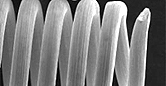

Wire coiling technology

Introducing our wire coiling techniques, to which filament manufacturing techniques are applied. We can handle coiling of soft materials, such as platinum, in addition to tungsten and molybdenum.

Heat treatment technology

Based on know-how accumulated and experience in handling refractory metal materials over the years, we choose the treatment method that best suits the specific use and purpose.

Welding technology

We have abundant welding techniques, including laser welding, resistance welding, and laser brazing. In product development, we choose the joining method that best suits the specific use and material.

Surface treatment technology

We take an optimum treatment method according to the use and material, including barrel polishing and surface cleaning using solvents.

Cutting technology

We choose a cutting method that best suits the specific material and shape of the workpiece, including cutting by machine tools and making the most of the workpiece material.

Grinding technology

Precision grinding technology is used to produce needles for a contact probe and a ionizer, a HID lamp electrode.

Machining Technology

We use CNC machines for precision machining of refractory metals such as tungsten and stainless steel. With our abundant experience in grinding technology and welding technologies including laser welding and resistance welding, we provide different shapes of machined products for specific applications.

|

[Head Office / Main Plant] |