Micro welding technique by YAG laser.

At Mitsuwa, we mainly perform laser processing using a YAG laser welding machine. Laser energy can be focused on an extremely small area, which makes the laser processing exactly right for welding and processing of micro materials.

Laser welding

Broad wire molybdenum is melted by making use of a difference in melting point between tungsten and molybdenum, so that the narrow wire tungsten is enclosed by the molybdenum to make a welded joint.

Laser brazing (joining metal to nonmetal)

Patent applied for

A brazing filler metal is used to make a brazed joint between a carbon fiber (nonmetal) and a W wire. A CW (continuous wave) YAG laser is herein used.

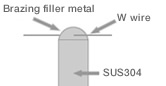

Laser brazing (joining metal to metal)

A brazing filler metal is used to make a brazed joint between a 0.5-mm-diameter SUS pin and a 20-mm wire. We are good at welding of such micro materials.

Types and characteristics of laser

| YAG | Y (yttrium), A (aluminum), and G (garnet). Wavelength is 1.064 mm. Producing a high energy density and capable of pulsed and continuous oscillation. |

|---|---|

| Co2 | Carbon dioxide laser Wavelength 10.6 mm High power and not good for pinpoint processing, but capable of continuous oscillation. |

| Excimer | Ultraviolet laser The shorter wavelength is 0.157 mm. Small energy. |

|

[Head Office / Main Plant] |