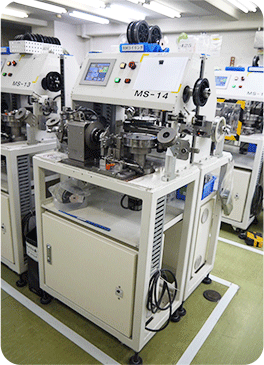

Winding

Diverse Winding Techniques for Precise Filaments

MITSUWA's winding technology supports various shapes,

such as continuous winding, variable pitch winding, double winding, and special winding.

We can precisely wind wires of very small diameters, and we offer support for

filament characteristics, shapes, and material selection issues.

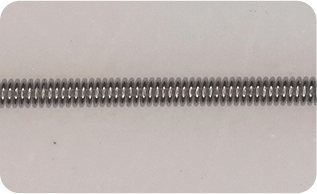

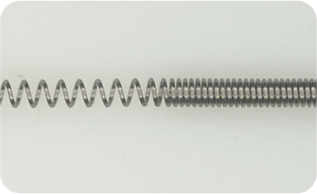

Continuous Winding Using Core Wire

Winding Type

- Continuous winding

- Double winding

- Variable pitch winding

*Please contact us for specific dimensions

| Type | Continuous Winding | Double Winding | Variable Pitch Winding |

|---|---|---|---|

| Wire diameter | 5µm- | 5µm- | 15µm- |

| Coil outer diameter | 27µm- | 135µm- | 75µm- |

| Coil length | 0.4mm- | 3.5mm- | 3.5mm- |

| Coil pitch Note 1) | 100% | Primary: 150% Secondary: 180% | 100%-240% |

| MD/WD ratio | 170% Note 2) | 140% Note 2) | 270% Note 2) |

Note 1: The coil pitch ratio in the table refers to our recommended values. Note 2: The MD/WD ratio refers to the ratio of the core wire diameter to the wire diameter, and for double winding, it refers to the primary winding ratio.

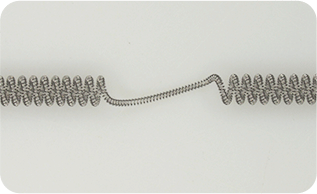

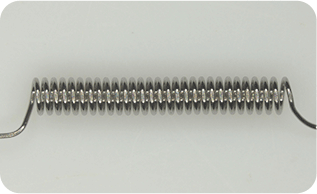

Core Wire Removal During Coiling

- Coil with legs (coil ends)

- Electrode

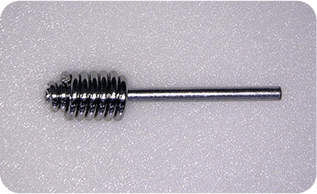

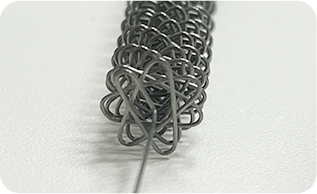

- Special coil / Porcupine element

*Please contact us for specific dimensions.

| Wire diameter | Continuous Winding | Electrodes |

|---|---|---|

| Wire diameter | 40µm- | 150µm- |

| Coil outer diameter | 75µm- | - |

| Coil length | -100 turns | 0.25mm- |

| Coil pitch Note 1) | 150% | - |

| MD/WD ratio | 500% Note 2) | - |

Note 1: The coil pitch ratio in the table refers to our recommended values.

Note 2: The MD/WD ratio refers to the ratio of the core wire diameter to the wire diameter.