Processing

MITSUWA's excellent processing technology is applied to various manufacturing areas,

from light bulbs to environmental and industrial equipment.

Explore our fine processing capabilities including winding, heat treatment, and joining techniques.

-

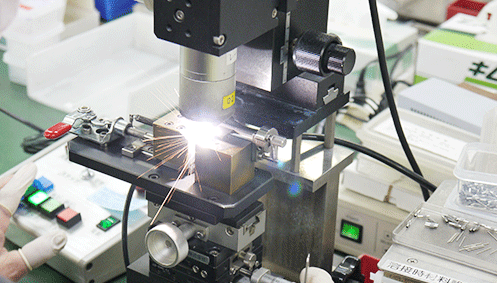

Welding

Micro welding technology using YAG laser and fiber laser. By locally irradiating energy, welding at the micron level is possible.

-

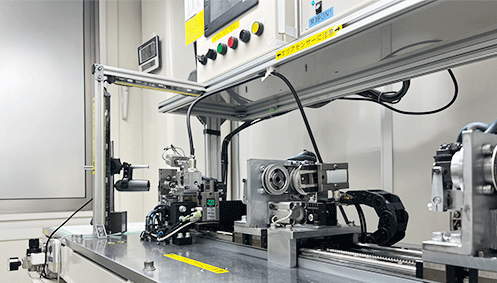

Assembly

We can assemble coils, parts, pins, and other components produced using our technology into finished assembly products.

-

Wire Drawing

We can draw wires from soft metals to hard metals and process them into pins or rods.

-

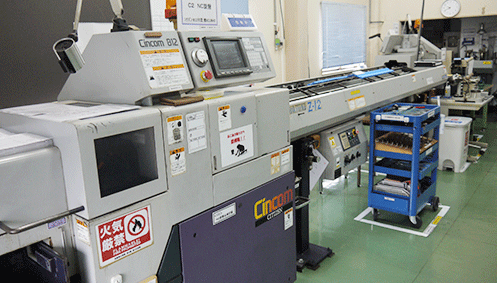

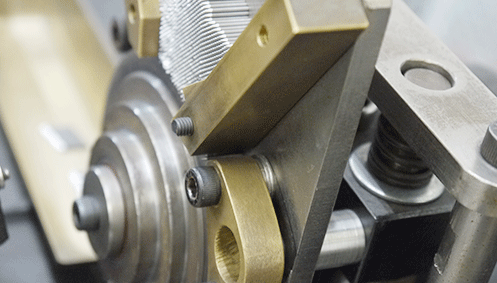

Machining

We perform precise machining of difficult-to-machine materials such as tungsten and stainless steel (SUS) using NC lathes. By leveraging existing technologies such as grinding and laser/resistance welding, we can handle various shapes.

-

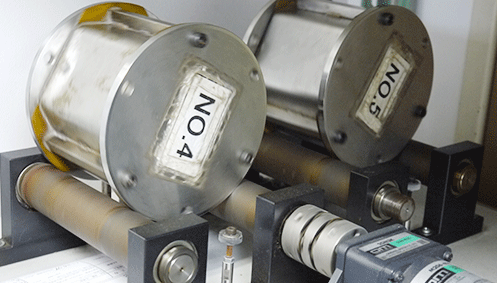

Heat Treatment

We perform high-temperature heat treatment of various metals and components using hydrogen treatment furnaces and vacuum treatment furnaces. This allows us to achieve degassing within metals, stress relief, and reduction, depending on the objective.

-

Surface Treatment

We offer various surface treatments to roughen or polish metal surfaces, and we can also perform deburring and edge rounding.

-

Grinding

We perform precision grinding and polishing to taper the tips of rod-shaped materials. This technique is used in various applications, including electrode components, needle-type probes, and ionizer electrode needles.

-

Cutting

We select cutting methods tailored to the material and shape of the processed products, utilizing machine processing and characteristics of the materials. The optimal cutting method is employed according to the specific requirements.

-

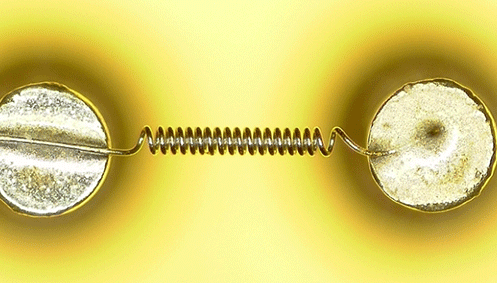

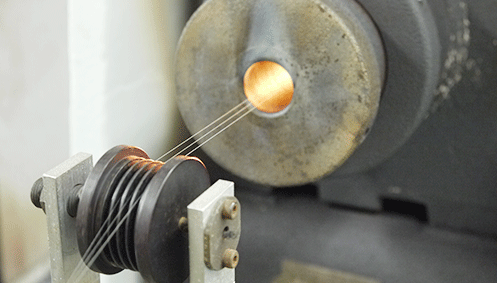

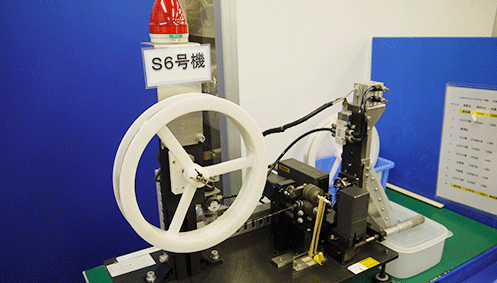

Winding

Introducing our winding technology adapted from filament manufacturing techniques. This includes winding of not only tungsten and molybdenum but also softer materials like platinum.