Surface Treatment

Diverse Surface Treatment Techniques

for a Polished Finish

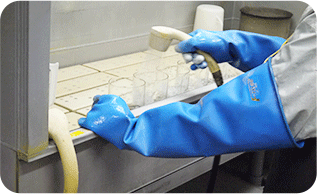

At MITSUWA, we utilize acids, alkaline solvents, and ultrasonic cleaning to perform surface cleaning and contaminant removal.

We also offer chemical dissolution of core wires and barrel processing for deburring and surface polishing.

Cleaning and Dissolution

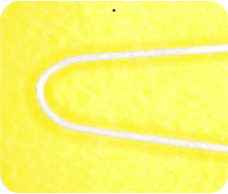

Filaments and electrodes require surfaces free from contaminants. To remove dirt accumulated during processing, we use ultrasonic cleaning and various chemicals, such as acid and alkaline solvents. Additionally, core wires made from molybdenum and iron used in filament production are dissolved and removed through chemical treatment.

- Ultrasonic Cleaning

- Nitric acid and sulfuric acid to dissolve core wires.

Other Examples

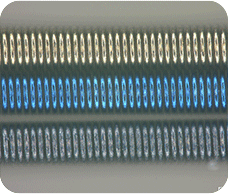

We offer chemical surface treatments like internal structure transformation through heat treatment and various mechanical processes such as edge rounding and mirror finishing. We can also coat metal surfaces with different materials upon request.

- Surface Oxidation Treatment

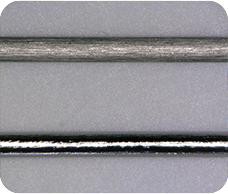

- Electrolytic Polishing

- Coating

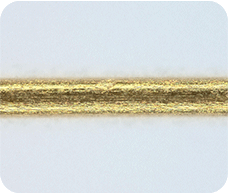

- Plating

Specifications

| Type | Surface Oxidation | Electrolytic Polishing | Coating | Plating |

|---|---|---|---|---|

| Material | Tungsten (W) | Tungsten (W) | Inquiry-based | Tungsten (W) Molybdenum (Mo) |

| Features | Enhances wettability, improves oxidation resistance at low temperatures | Provides a smooth, glossy finish | Enhances corrosion and wear resistance | Decorative finish, enhances corrosion and wear resistance |