Grinding

Versatile Grinding Techniques

Utilizing Needle Processing Technology

We perform precision grinding and polishing to taper or plane grind the ends of rod-shaped materials.

This technique is used in various applications, including electrode components,

needle-type probes (wire probes), and ionizer electrode needles.

Tip Processing

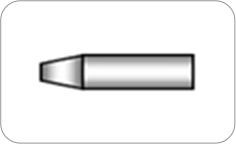

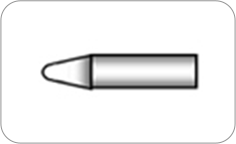

Tip Shapes

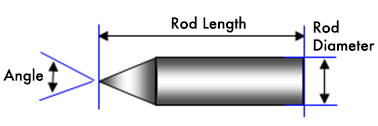

We process tips into various shapes, such as pointed or rounded, based on your specific needs. The length of the conical part can be freely adjusted by modifying the grinding angle. Additionally, it is possible to process both ends into the same shape.

- Cone

- Flat

- Ball Point

- Round

Processing Specifications

| Angle | 15°-180° |

|---|---|

| Rod Diameter | φ0.3mm-φ3.0mm |

| Rod Length | 10.0mm-50.0mm |

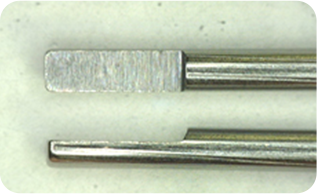

Flat Surface Grinding

- 1D-cut processing

- 2H-cut processing

Flat Surface Grinding

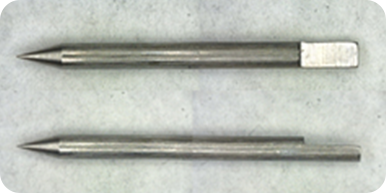

Integration with Existing TechnologiesWe can combine existing technologies, such as taper processing and cutting, for complex processing. For example, we can perform groove processing, D-cut/H-cut with an NC lathe, and then precision grinding/polishing for taper processing or laser/resistance welding of rods and coils. Please feel free to consult us about shapes.

Grinding Technology Applicable to Various Materials

We excel in taper processing and flat surface grinding for difficult-to-process materials, such as tungsten and SUS (stainless steel). We can handle either customer-supplied materials or arrange materials ourselves.

- Material: Tungsten

Rod Diameter: 2.0mm

Rod Length: 20.0mm - Material: Brass

Rod Diameter: 1.0mm

Rod Length: 15.0mm - Material: Stainless Steel

Rod Diameter: 0.5mm

Rod Length: 20.0mm - Material: Molybdenum

Rod Diameter: 0.7mm

Rod Length: 15.0mm