Verification

We support customers from initial development to stable mass production,

while a wide variety of measurement and analysis tools are used for quality evaluation.

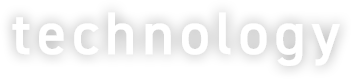

High-Precision Image Dimension

Measuring Instrument

For dimensional measurement, the IM series from KEYENCE is used for quality control. It enhances the measurement reliability by avoiding measurement variations due to individual differences among operators and measurement conditions.

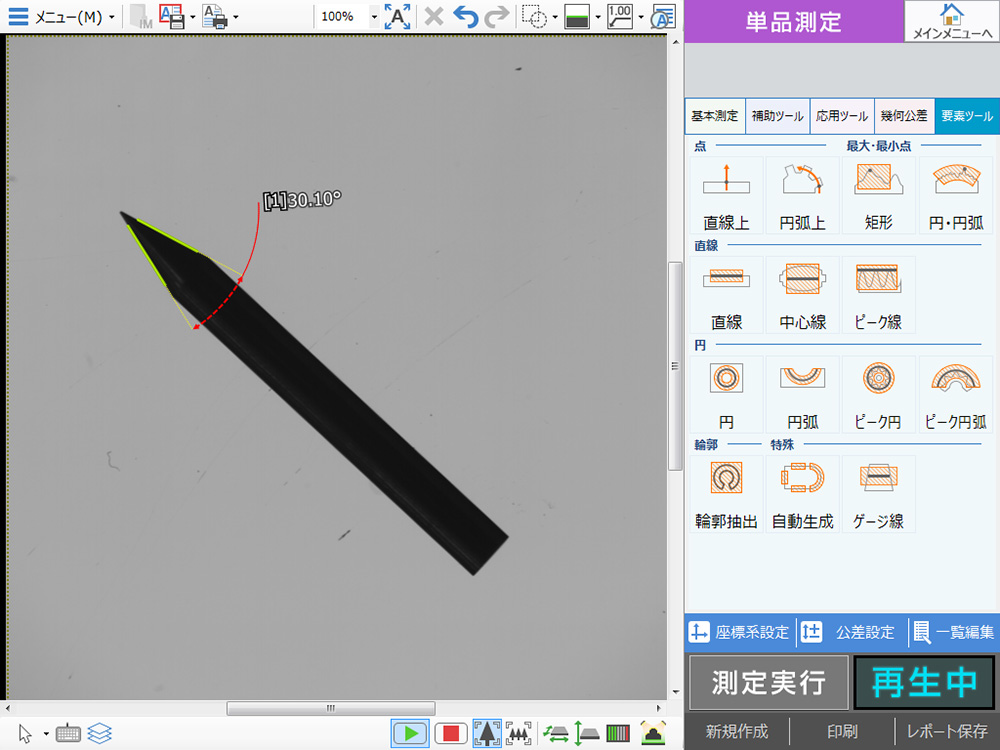

3D Measuring Instruments

For 3D measurement including dimension, shape, surface roughness of prototypes, we use KEYENCE's VR series and Mitutoyo's CNC measuring machines. These non-contact 3D measuring systems facilitate profile measurement without damaging the samples.

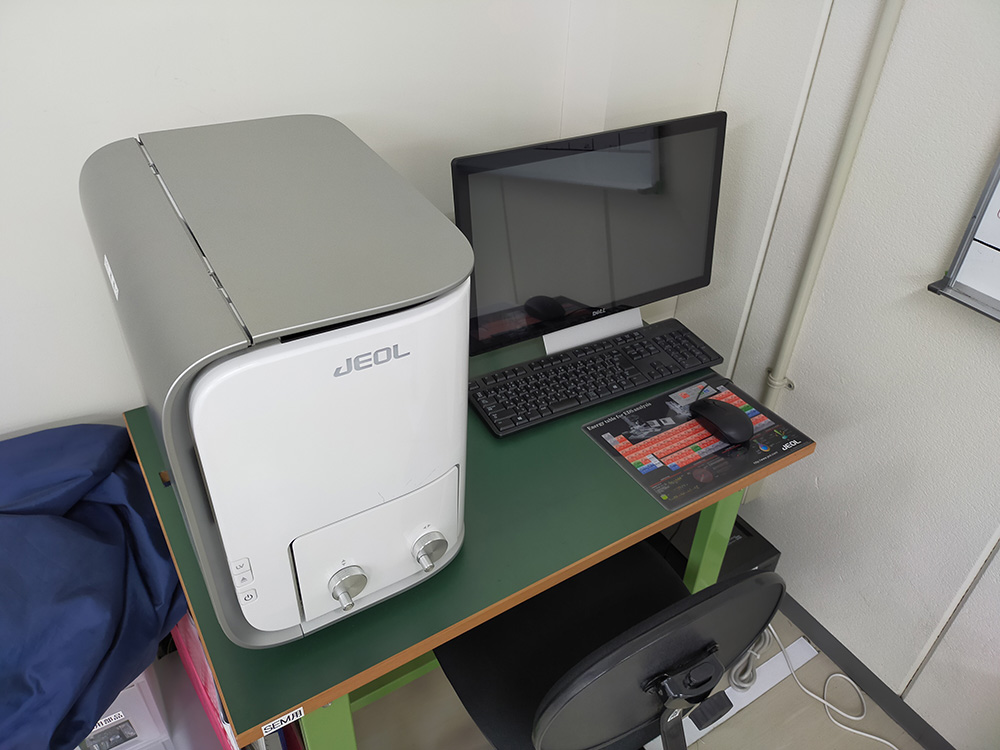

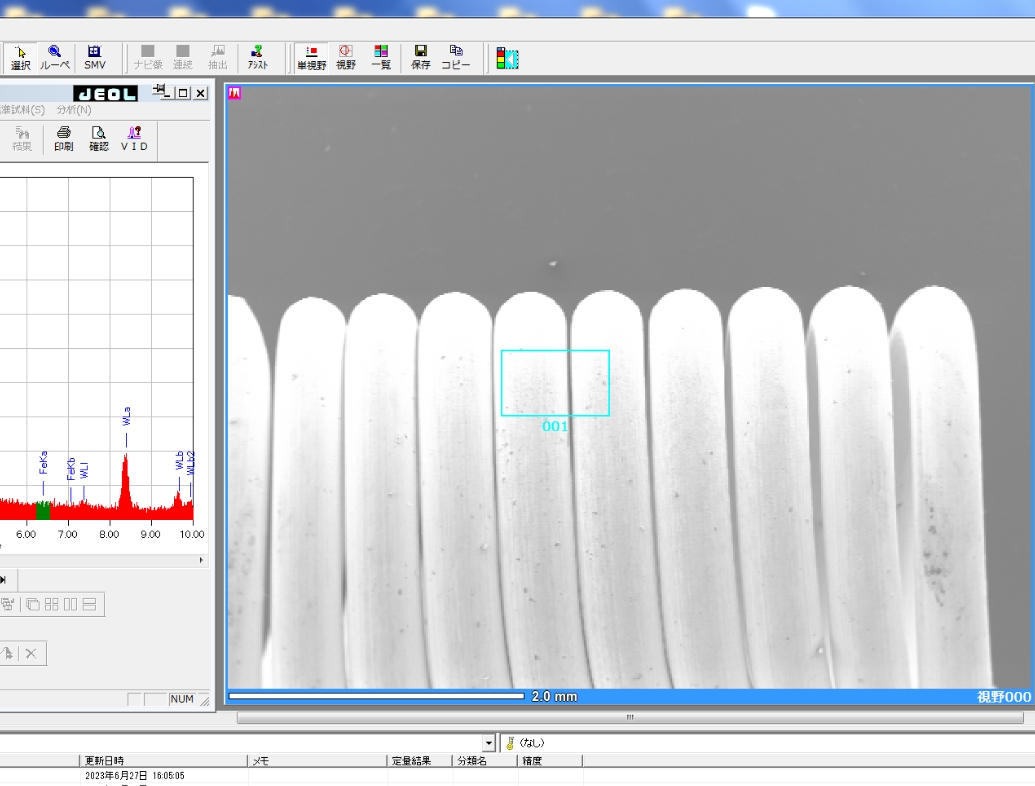

Dispersive X-ray Analyzer

For qualitative and quantitative elemental analysis, the energy dispersive X-ray analyzer from JEOL is used. Not only the elemental analysis of materials, but also contamination check on products for quality assurance.

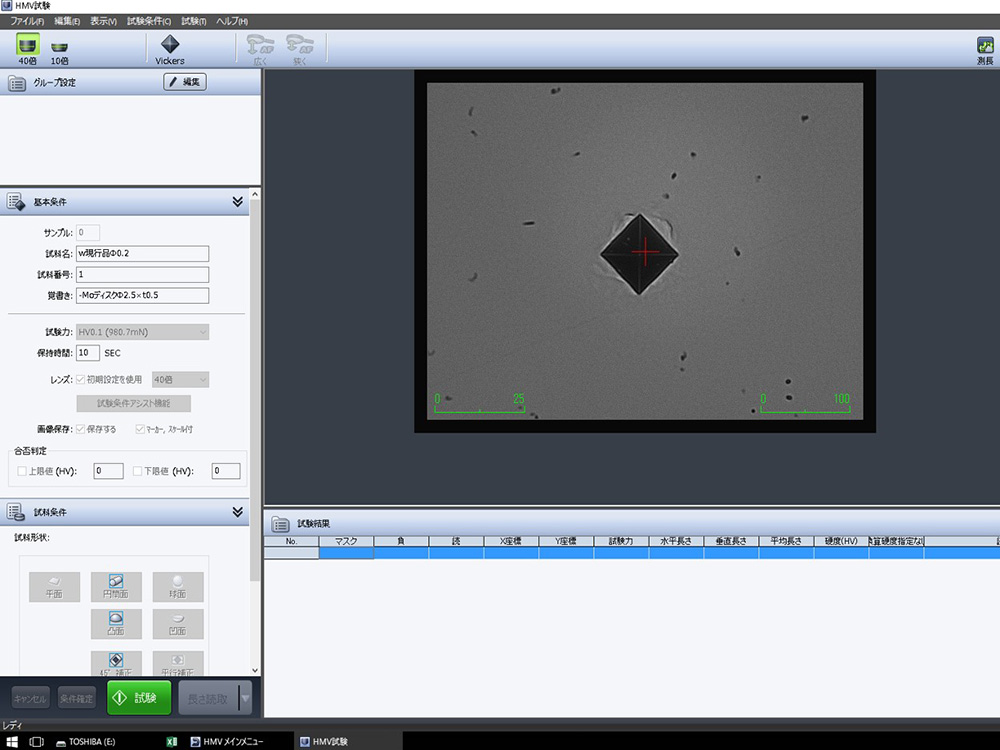

Micro Hardness Tester

For hardness measurement, the HMV series micro-Vickers hardness tester from Shimadzu is used to evaluate products in terms of hardness of materials and hardness change after heat treatment.

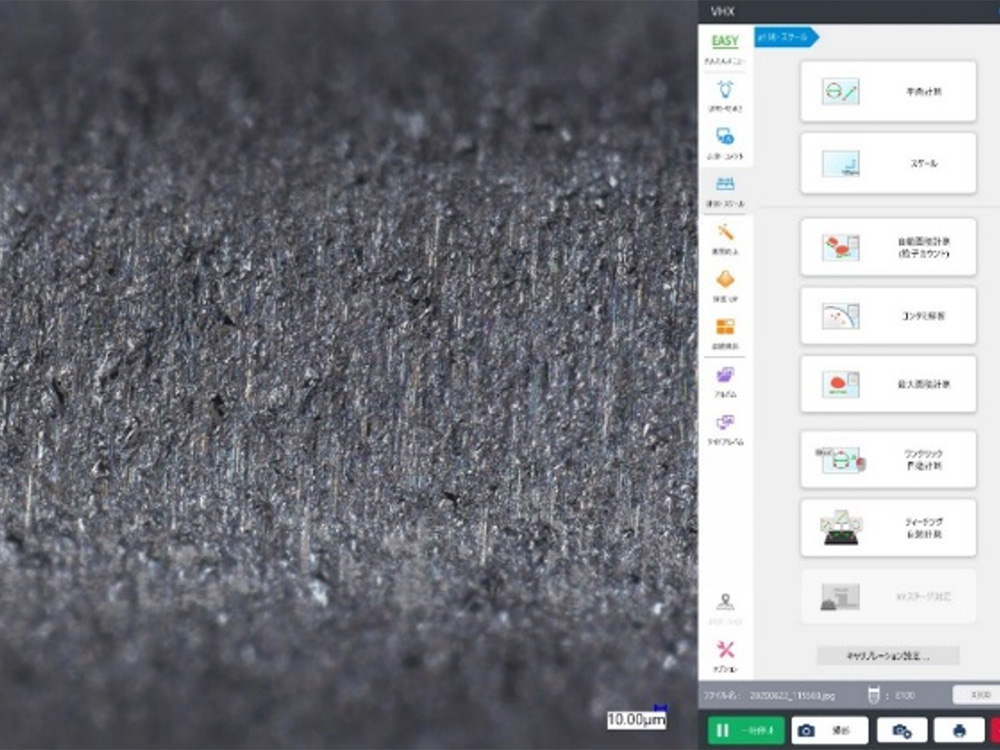

Ultra High Resolution Microscope

For surface observation of materials and products, the VHX series digital microscopes with high magnification and high resolution from KEYENCE is used. It enables observation and evaluation of samples that cannot be observed with a stereo microscope.

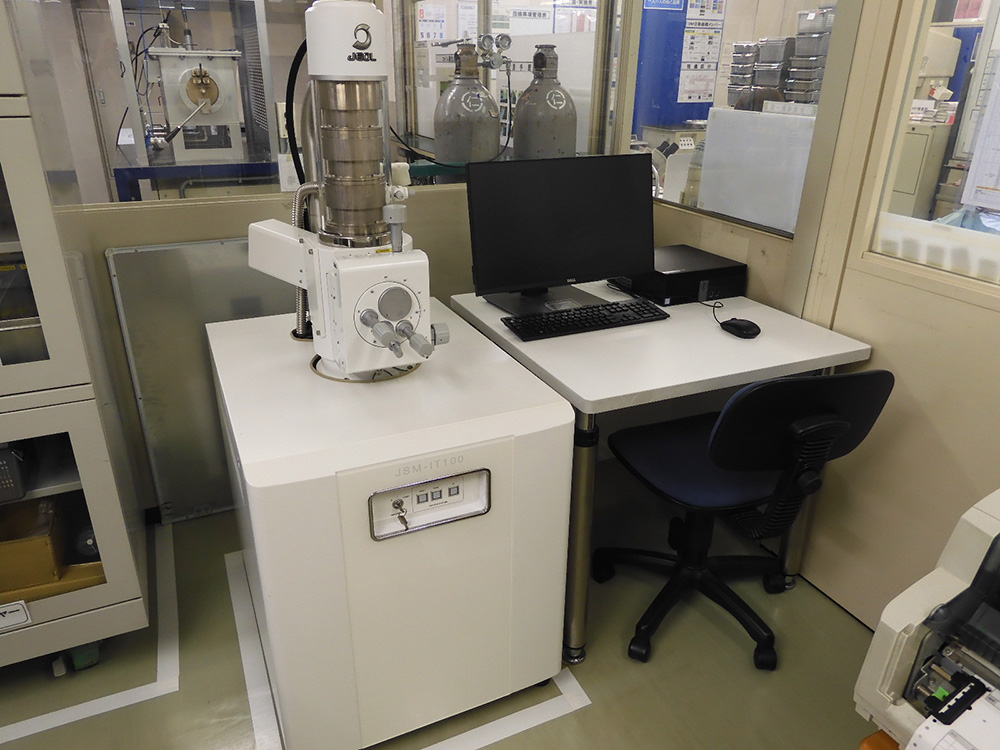

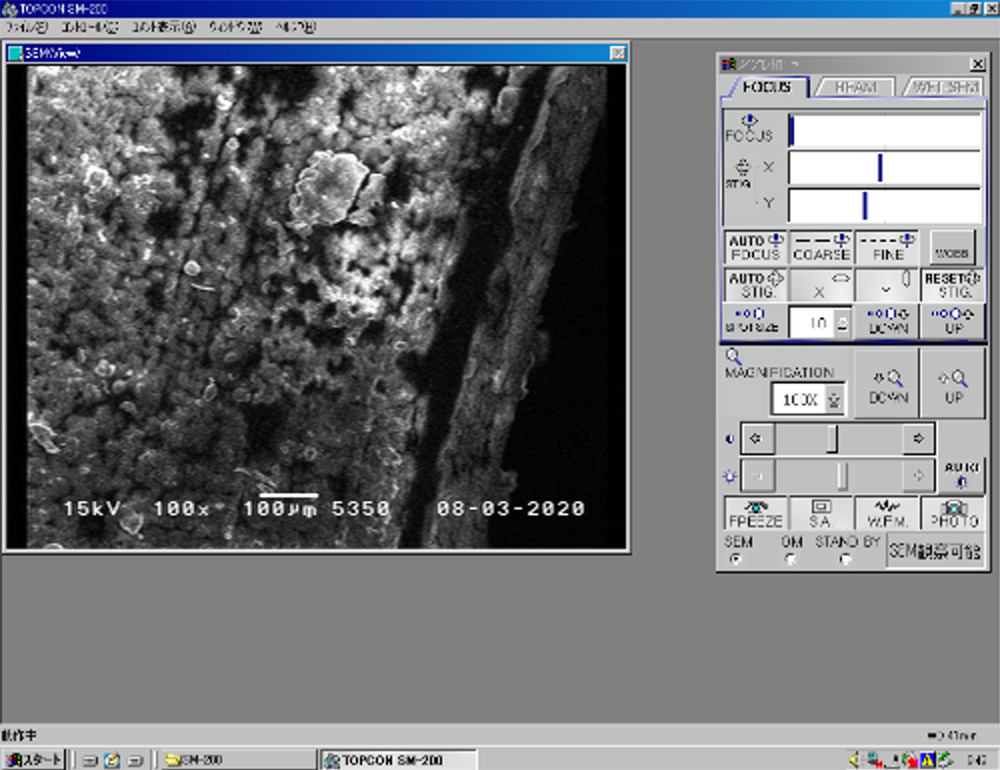

Scanning Electron Microscope (SEM)

For object surface that cannot be observed with microscopes, a scanning electron microscope (SEM) is used. As a company specializing in microfabrication, we have been an early adopter of SEM which is widely used internally.

Stereo Microscope /

Length Measuring Microscope

As a company specializing in micro processing and assembly, stereo microscopes and measuring microscopes play important roles for products' dimension and appearance check.