MITSUWA's Strengths

Unique Technologies

Since its founding in 1933, MITSUWA has been involved in the manufacturing of various finely processed parts for lighting, industrial, and consumer use. The processing technology we have accumulated over the years is our greatest strength. By utilizing a variety of unique technologies that cannot be imitated by others, we aim to be the global niche leader in all fields where fine metal processing thrives.

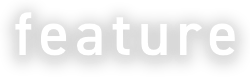

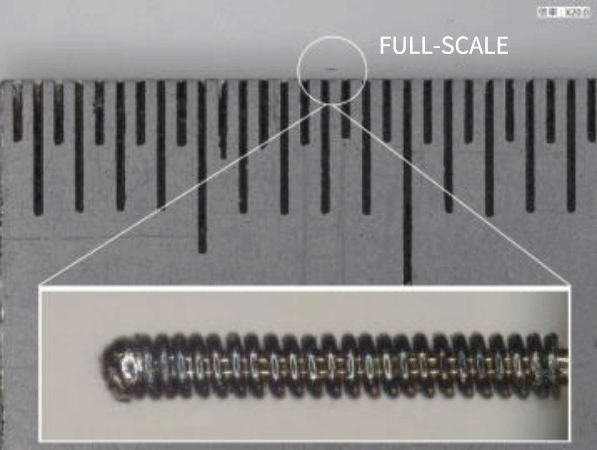

1. Winding Technology for Producing

the World's Smallest Metal Coils

By applying the winding technology we have cultivated through many years of producing fine filaments, we have managed to create metal wires with a diameter of just φ0.003mm, formed into a coil with an outer diameter of φ0.027mm. We are capable of handling not only round wires but also micro coils made from flat wires, which are currently used as tiny springs and electronic components. In response to market needs, we continue to enhance our technology to produce even smaller coils.

The "Made in Shinagawa" PR project is a system in which the Shinagawa Ward certifies superior products and technologies developed and realized by companies within the ward, and our micro coils were selected as certified products in FY 2014.

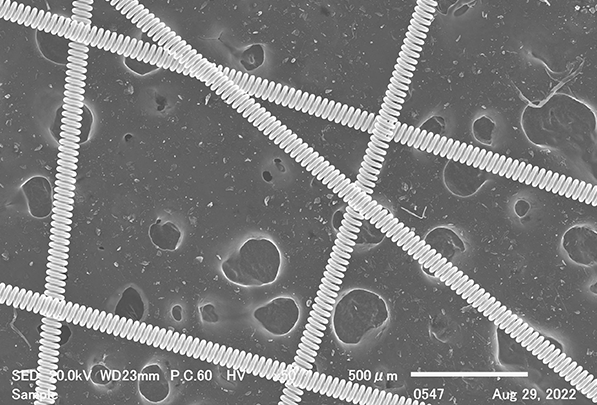

2. Grinding and Cutting Technology

Specialized for Hard Materials

We excel in processing bar materials with diameters ranging from φ0.5 mm to 3.0mm, which are relatively less processed. The tip can be finished to a micron level, and we have a track record of use in various fields, including ionizer probes and medical electrodes. Additionally, in cooperation with material and grinding stone manufacturers, we provide high-quality, low-cost products in the grinding of difficult-to-process materials such as tungsten and silicon.

3. Assembly and Welding Technology

for Micro Parts

We can assemble and perform partial welding of micro parts, which are difficult to handle. We particularly excel in fine welding using lasers and can propose the most suitable processing methods according to the location, range, and strength of the desired joint.

Solution Proposals and

Mass Production Capabilities

We accurately understand the purpose of our customers' requests and actively propose solutions to solve any arising issues. For mass production, we not only propose manufacturing methods but also develop, design, and produce manufacturing equipment in-house to be used as mass production equipment tailored for a vast variety of products.

Features of the Development, Design,

and Manufacturing Process

Customer Support

Our services are always aligned with our customers' needs. Not only do we faithfully execute requests, but we also accurately understand the purpose and propose solutions to address our customers' challenges.

Development

We have a spirit of constantly challenging new things without being bound by existing processing technologies. We maintain a flexible development system to meet our customers' requests.

Design

We can support product design according to required specifications and requests. We can design jigs, tools, and manufacturing equipment tailored to the products in-house.

Procurement

From general metals to rare metals, we can procure materials not only domestically but also from overseas, including China, Europe, and the United States, considering quality, price, and delivery time.

Manufacturing

In addition to in-house processing, heat treatment, joining, assembly, and surface treatment, we offer one-stop manufacturing through our manufacturing network. We specialize in fine processing and welding, such as micro-coiling, micro-grinding, micro-welding, and micro-assembly. We can shape your specifications into products and propose manufacturing methods.

Quality Control

We have a quality control system that meets the requirements of ISO 9001. We verify quality using various measurement, testing, and inspection equipment such as optical inspection devices, scanning electron microscopes (SEM), hardness testers, and tensile testing machines.

Harnessing Diversity

as a Strength

From young staff to mid-career and senior specialists, individuals of various ages, genders, and nationalities with diverse backgrounds are thriving in the right positions. Our company culture values diversity, and by aligning various unique perspectives, we create significant strength.

Achieving

a Global Niche Top Position

By leveraging our unique and core technologies, we have achieved several global niche top positions. By developing and marketing new products and responding to new inquiries, we aim to further expand our leading share in the market.

Filaments

for Miniature Automotive Lamps

Electrodes

for Mass Spectrometry

Ionization Electrodes

Charge Wires

for Copiers