Surface treatment technology

Mitsuwa Electric performs surface cleaning and foreign matter removal procedures using acid-alkali solvent or ultrasonic waves. It can also dissolve core wires using chemicals and perform deburring and barreling for surface polishing.

Cleaning with chemicals and ultrasonic waves. Dissolving core wires with chemicals.

Filaments and electrodes must be kept free from foreign matter deposited on them. Ultrasonic cleaning or cleaning using chemicals such as acid/alkali solvents is performed to remove any contaminants on the filaments and electrodes deposited while they are being processed. The molybdenum and iron used as the core wire for the manufacture of filaments are dissolved using chemicals.

Ultrasonic cleaning |

Dissolving core wires using nitric acid or sulfuric acid |

Mechanical treatment

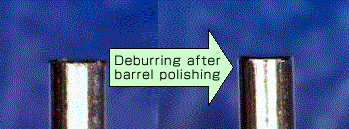

Mechanical treatment involves removing burrs produced during cutting operations and barreling for finishing the part surface. The medium, time, and other conditions are set for each product to control the surface finish (satin to mirror finish).

|

|

[Head Office / Main Plant] |